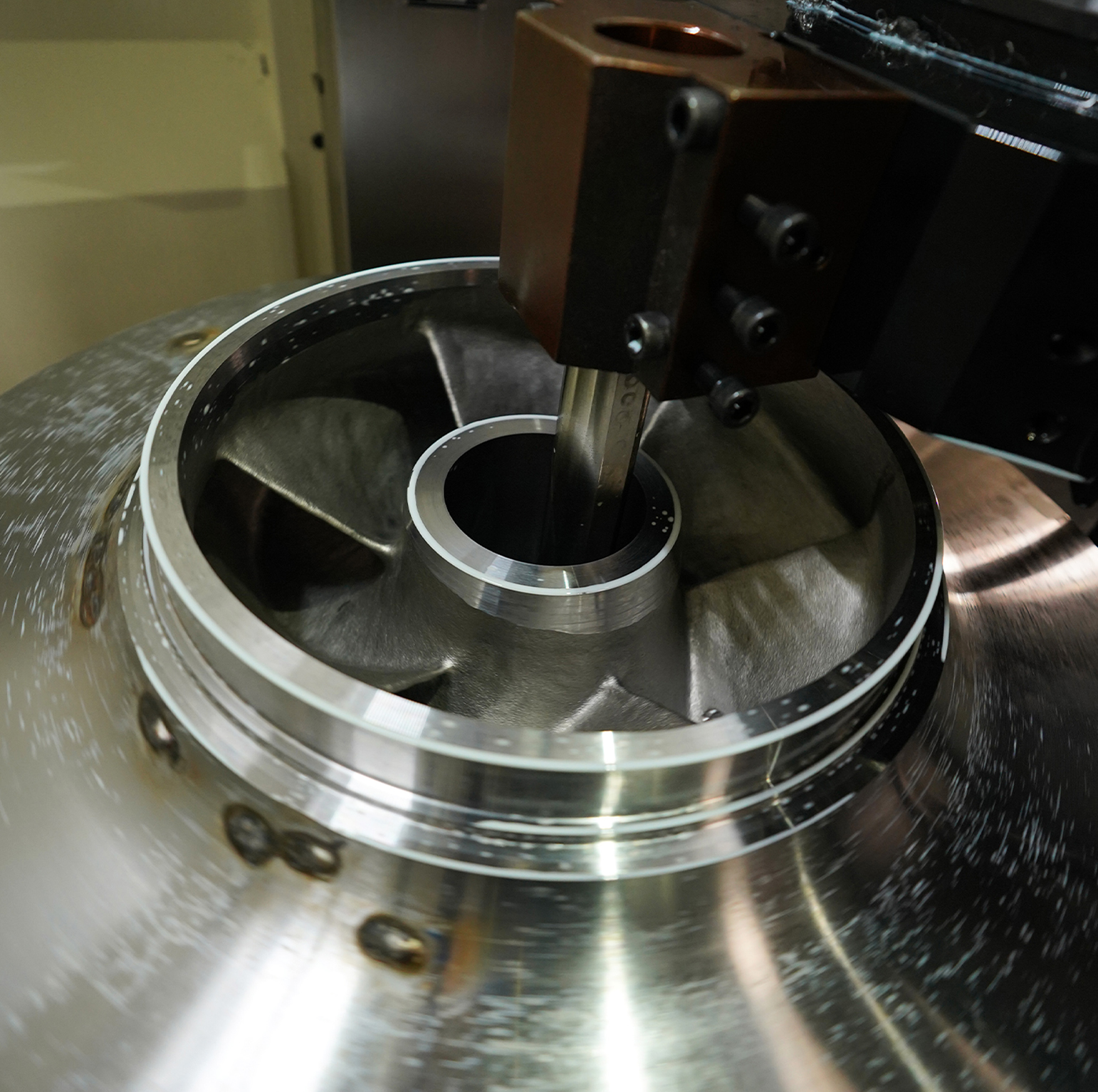

- Dimensional Accuracy– Tight tolerance control using calibrated tools

- Surface Finish– Clean edges, smooth finishes, zero compromise

- Inspection Tools– Micrometers, Gauges, and CMM (Brown & Sharpe 7-10-7)

- Process Monitoring–Real-time checks and adjustments during operations

- Documentation– Batch-wise records for traceability and compliance

© Copyright 2025 | Built and maintained by Pace Media