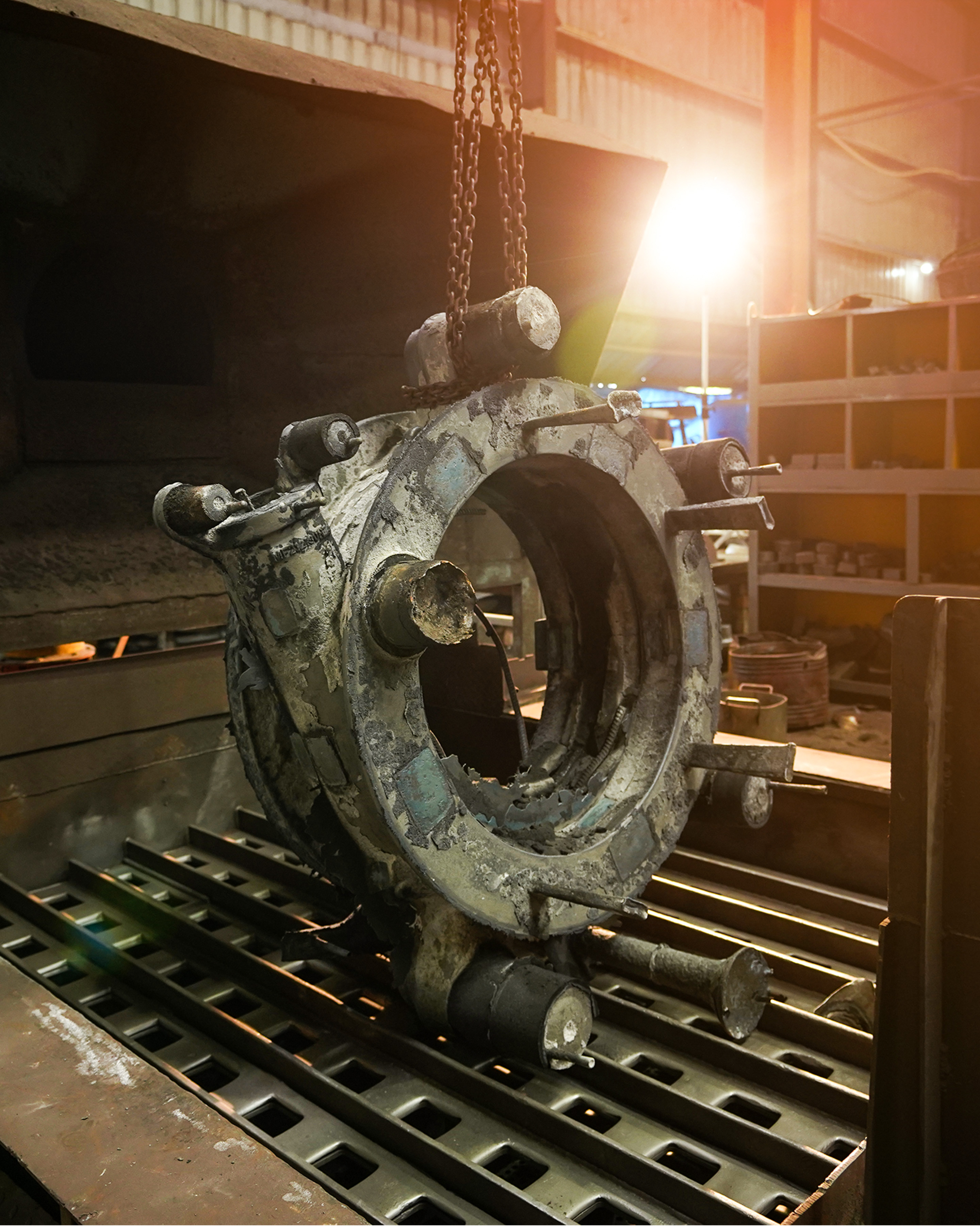

State-of-the-art foundry delivering high-quality castings with precision, consistency, and strength. We serve critical sectors such as Energy, Marine, Heavy Engineering, etc., where performance can’t be compromised.

- Carbon Steel, Stainless Steel, Corrosion-Resistant & Special Alloys

- Casting Weight: Up to 1.2 MT

- Monthly Capacity: 300 MT

- Facility Size: 30,000+ sq.ft (expanded)

- Max Finished Casting: 650 kg