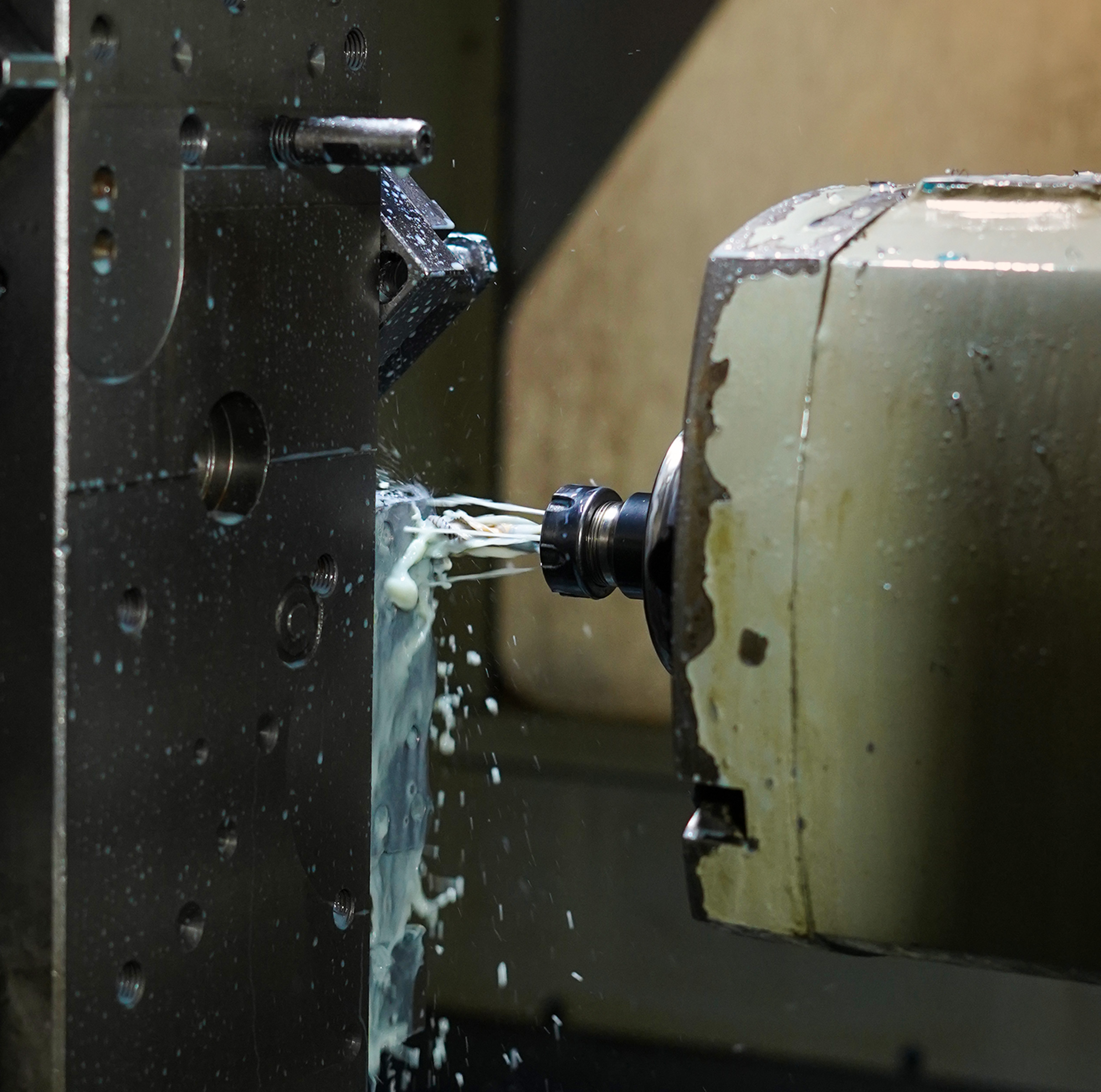

All machining processes at GWASF are backed by stringent inspection systems to ensure dimensional accuracy, structural integrity, and performance under load.

© Copyright 2025 | Built and maintained by Pace Media

All machining processes at GWASF are backed by stringent inspection systems to ensure dimensional accuracy, structural integrity, and performance under load.