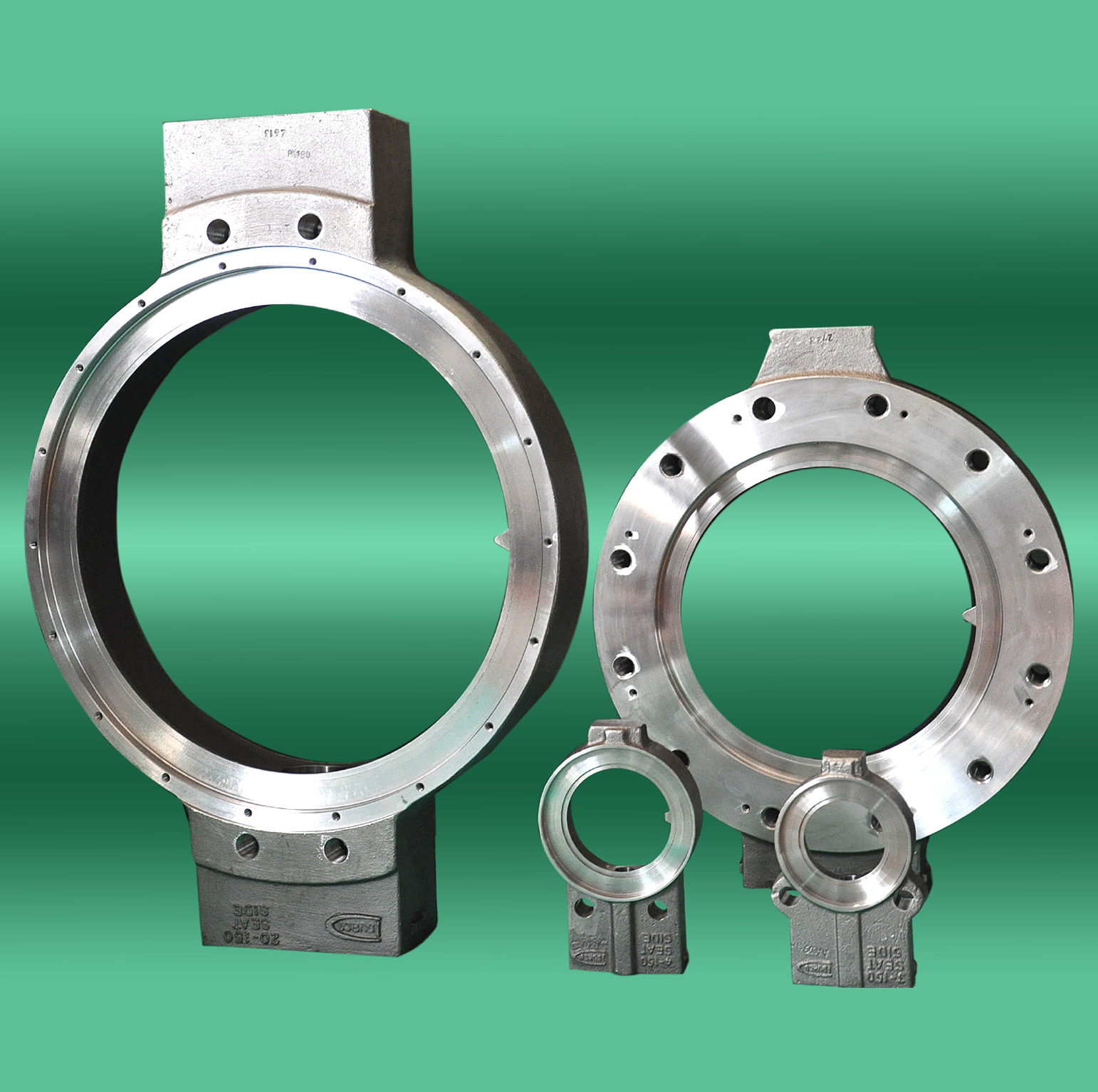

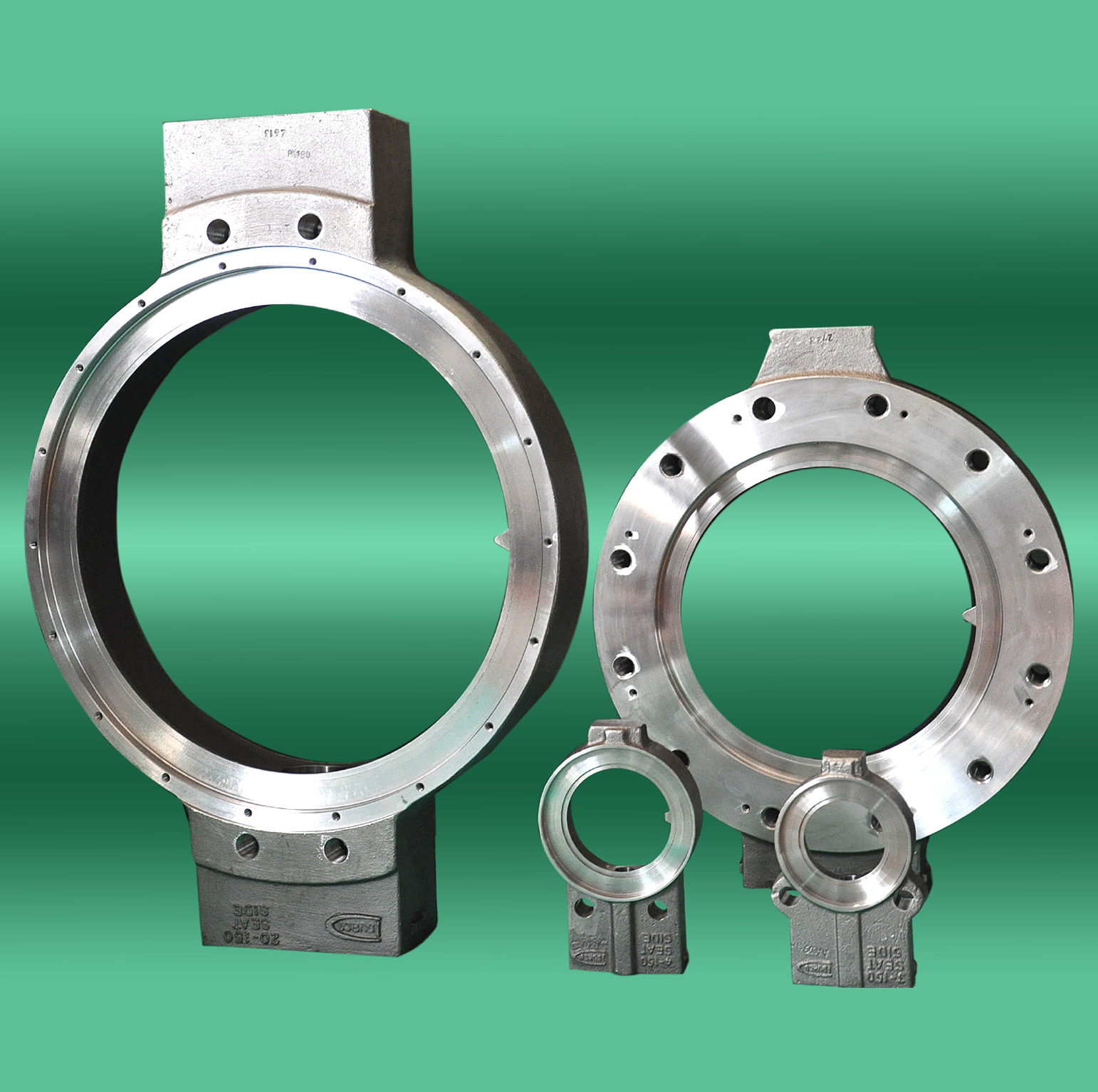

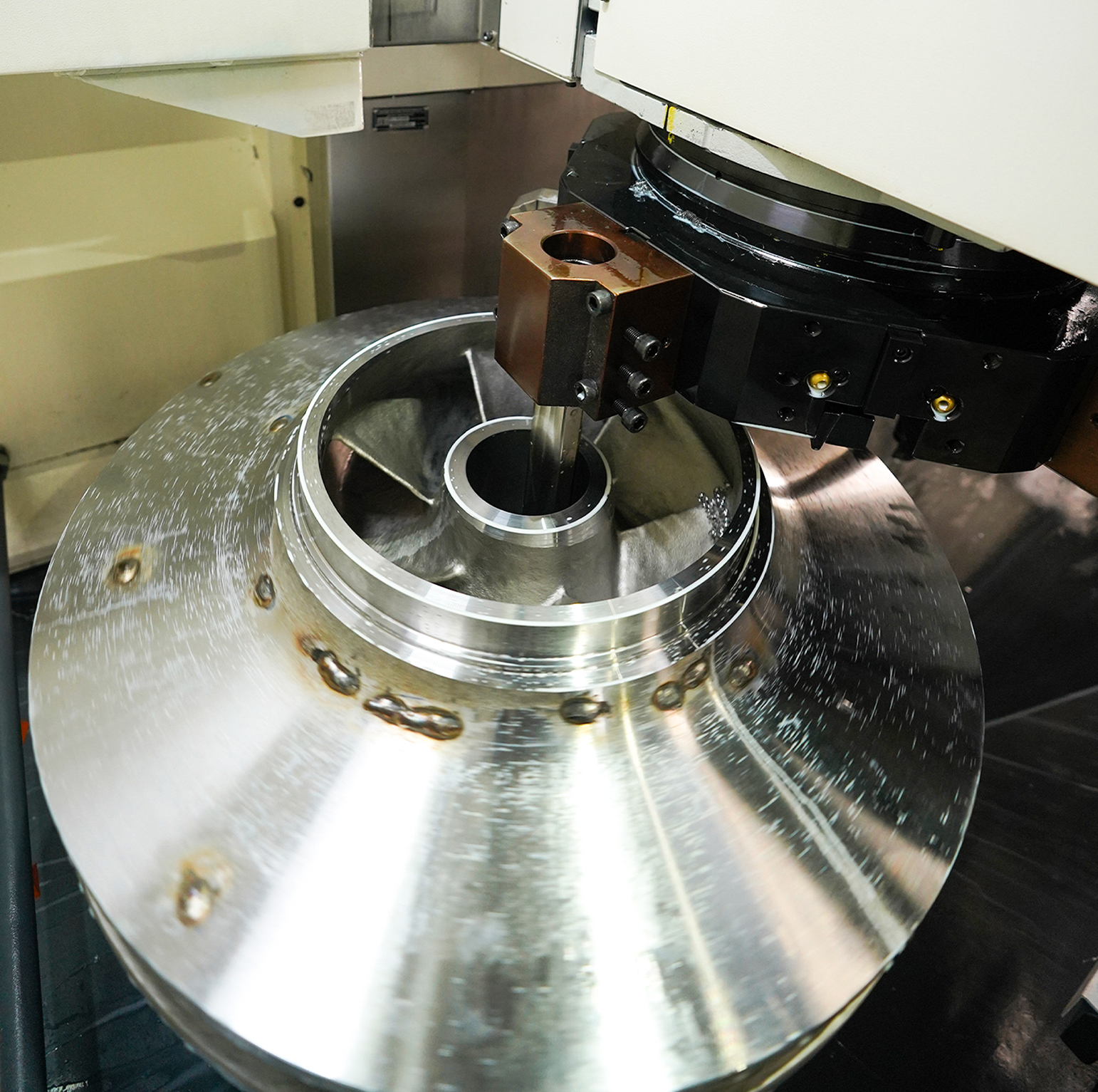

Every casting is engineered with precision, tested for performance, and validated to meet global standards.

© Copyright 2025 | Built and maintained by Pace Media

Every casting is engineered with precision, tested for performance, and validated to meet global standards.